10

2024

-

12

Technology empowers traditional crafts: Innovation and application of modern bead embroidery in Shaoxing Keqiao's textile industry

Introduction to Modernized Beaded Embroidery

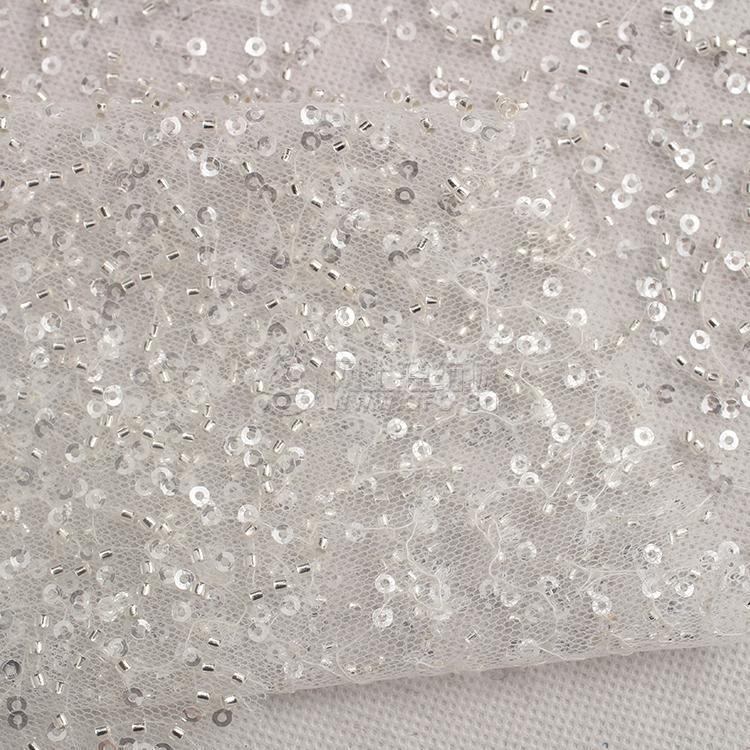

With technological advancements, traditional beaded embroidery has undergone modernization. Through automated equipment, innovative materials, and digital design, production efficiency and process precision have been significantly improved. Modernized beaded embroidery retains the exquisite feel of traditional handcrafts while better adapting to current diverse and personalized needs. It is widely used in clothing, home furnishings, and handicrafts.

Technical Characteristics of Modernized Beaded Embroidery

1. Digital Design

Using computer-aided design (CAD) technology, beaded embroidery patterns can be created using professional design software. Designers can precisely control the pattern's color, size, arrangement, and stitching method, avoiding the uncertainties of manual design.

2. Automated Equipment

Modernized beaded embroidery machines can achieve large-area embroidery through programming. The equipment can precisely control stitch density, bead size, and sequin arrangement, effectively improving production efficiency.

- Multi-functional embroidery machine: Supports simultaneous completion of beads, sequins, and ordinary embroidery.

- High-speed embroidery machine: Suitable for mass production, quickly completing complex patterns.

3. Application of New Materials

- Environmentally friendly materials: Uses biodegradable glass beads, sequins, and other materials, responding to the concept of green production.

- Lightweight beads: Uses lighter, more durable materials (such as synthetic resin beads) to reduce product weight and improve comfort.

- Intelligent wires: Uses highly elastic and wear-resistant embroidery threads to improve the firmness and lifespan of beaded embroidery.

4. Intelligent Control System

Automated beaded embroidery machines are equipped with an intelligent monitoring system that can detect errors during the embroidery process in real-time and automatically adjust to ensure the accuracy and aesthetics of the pattern.

5. Modular Production

By breaking down the embroidery process into modules such as design, material preparation, machine embroidery, and post-processing, each stage achieves streamlined operations, significantly improving production capacity while reducing manual intervention.

Modernized Process Flow

1. Digital Pattern Design

Using design software to generate embroidery schemes, simulating bead arrangement effects and optimizing them.

2. Material Selection and Preparation

Selecting appropriate beads, sequins, and embroidery threads according to the design scheme. Materials are sorted by color to facilitate machine operation.

3. Machine Programming and Debugging

Uploading the design file to the embroidery machine, setting embroidery parameters, including stitch spacing, bead size, and arrangement density.

4. Automatic Embroidery

The machine automatically completes the main work of beaded embroidery according to the programming. For complex or special patterns, manual fine-tuning can be combined.

5. Post-processing and Finishing

Shaping, trimming threads, and repairing the finished product to ensure that the embroidered pattern is neat and beautiful.

6. Quality Inspection

Using optical testing equipment to check the firmness of the beads, the integrity of the pattern, and the overall effect to ensure that the product meets high-quality standards.

Advantages and Innovation

1. Efficiency Improvement

Automated equipment enables large-scale and rapid production, especially suitable for mass production in the fashion fast-moving consumer goods industry and high-end custom clothing.

2. Cost Control

Modernized processes reduce the need for manual labor, reducing production costs while ensuring exquisite results.

3. Improved Accuracy

Digital design and intelligent control ensure high fidelity of the embroidery pattern, achieving complex details that are difficult to achieve with traditional handcrafts.

4. Sustainable Development

Using environmentally friendly materials and green production technologies, responding to the trend of sustainable development while enhancing product added value.

Applications

1. Fashion Industry

Beaded embroidery is widely used in high-end fashion, wedding dresses, and evening gowns, showcasing luxury and personalized design.

2. Home Decoration

Modernized beaded embroidery is used in high-end pillows, curtains, tablecloths, etc., enhancing the decorativeness of indoor spaces.

3. Cultural and Creative Products

Beaded embroidery combined with modern art design creates handicrafts or gifts with ornamental and collection value.

4. Stage Costumes and Film and Television Props

The dazzling effect and three-dimensionality of beaded embroidery meet the special needs of stage costumes and props, enhancing visual impact.

Modernized beaded embroidery technology combines traditional craftsmanship with technological innovation, continuing the charm of traditional culture while expanding its application fields and commercial value. It plays an important role in the contemporary textile industry.

RELATED INFORMATION

Spring breeze, all things budding——The 2025 China National Textile and Apparel Council Spring Joint Exhibition grandly opened at the Shanghai National Exhibition and Convention Center