10

2025

-

02

New year, new look. Guiling Textile Co., Ltd. will continue to work with customers.

Zeroing Textiles' Three Technological Upgrades Usher in a New Era of Textile Innovation

The year 2025 ushers in a new era of high-quality textiles. With the arrival of the new year, Zeroing Textiles Company has taken the lead in the industry by announcing that it will fully upgrade and promote three core technologies—"precision printing, bead tube embroidery, and laser embroidery"—to meet the growing customer demand for high-quality, personalized textiles and to help the entire textile market move towards a new stage of innovation and high-end development.

Precision Printing Reshapes Textile Design Aesthetics

Zeroing Textiles employs advanced "precision printing" technology. Through a high-precision digital control system, design patterns are precisely positioned on the fabric at various key locations, ensuring that each product in mass production presents a consistent and refined printing effect. This technology not only significantly improves the controllability and stability of the design but also provides a broader creative space for various fields, such as clothing and home textiles. This technology is particularly important in fashion apparel, sportswear, home textiles, and high-end custom clothing. For example, designers can design unique patterns in specific areas (such as collars, cuffs, or hems) and ensure that each finished product maintains high consistency during mass production. Precision printing also supports "multi-layered superposition" and "multi-color combinations," making the patterns on the fabric more three-dimensional and vivid, satisfying the market demand for high-end personalized designs. Using this technology, designers can achieve multi-layered, multi-color overprinting effects, bringing the product to an international standard in terms of both visual appeal and texture.

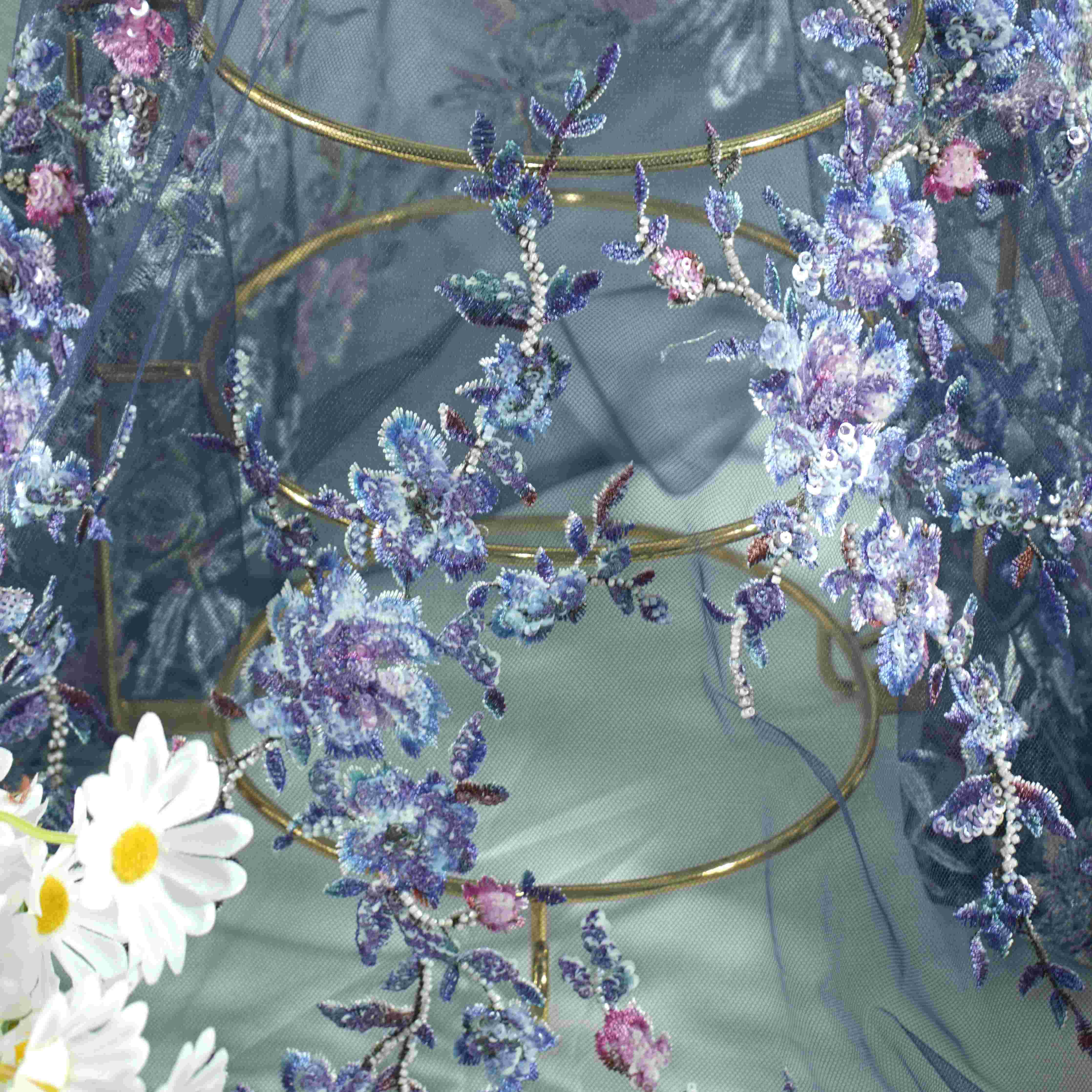

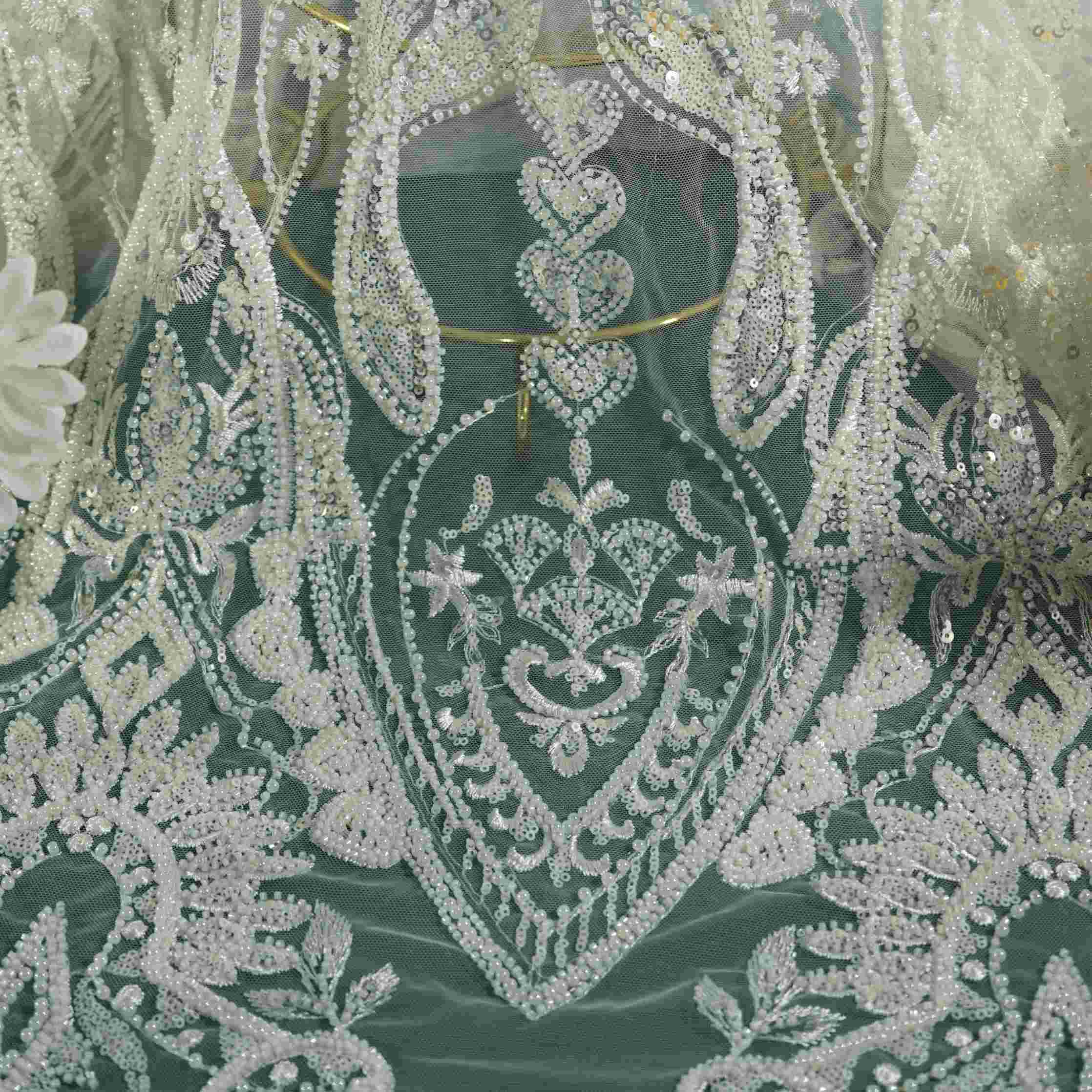

Bead Tube Embroidery Craftsmanship Creates a Three-Dimensional Luxurious Texture

As a major innovation in the field of textile decoration, the "bead tube embroidery" process combines carefully selected beads with special techniques and uses automated equipment for three-dimensional embroidery on the fabric, showcasing a unique luster and layering. This technology not only enhances the decorative effect of the product but also gives clothing, wedding dresses, and home decorations a luxurious and refined texture. It is understood that Zeroing Textiles has successfully applied this technology in several high-end projects. The presentation effect has received much attention on new media platforms, such as the large number of views and positive comments on related process videos on Douyin (TikTok).

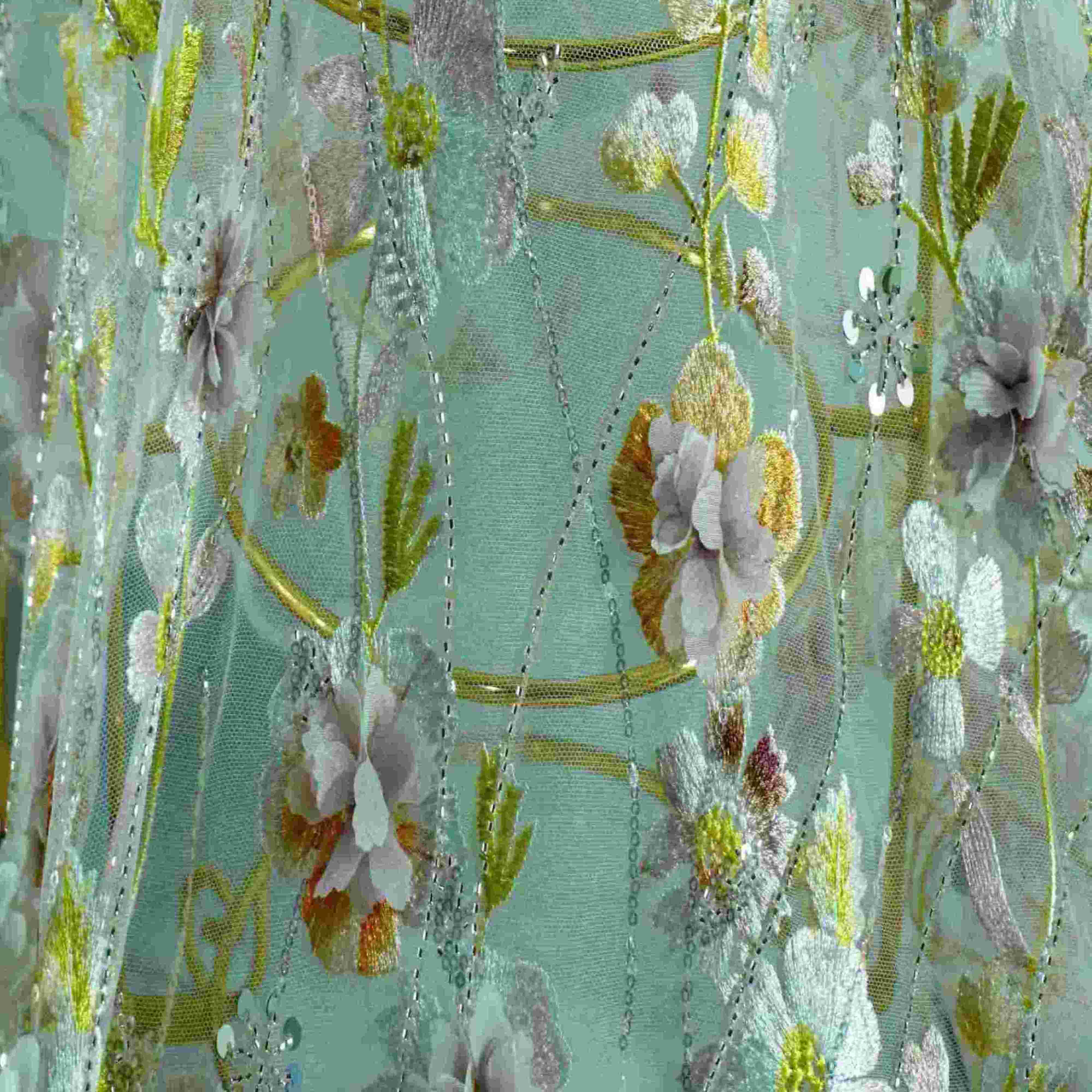

Laser Embroidery Innovation Breaks the Limits of Traditional Embroidery

On the path to pursuing precision and innovation, Zeroing Textiles has introduced "laser embroidery" technology. This technology uses a laser beam for precision carving on textiles, achieving diversified effects such as hollowing, gradation, and embossing, giving traditional embroidery a new life. Compared with traditional embroidery, laser embroidery is more precise and can achieve "complex gradient effects and extremely fine patterns," even presenting "a contrast of multiple materials" in three-dimensional design on the same fabric. Laser embroidery not only enhances the artistic expressiveness of the product but also broadens the application range of textiles in fashion design. Combined with other decorative techniques such as metallic threads and sequins, this technology makes each product unique, satisfying consumers' pursuit of creative design and quality experience.

New Year Outlook: Quality-Driven and Technological Innovation

Zeroing Textiles Company stated: "In the new year, we will take 'quality-driven, innovation-leading' as the core of our development, and through continuous upgrades and optimization of the three major technologies of precision printing, bead tube embroidery, and laser embroidery, we are committed to providing customers with higher-quality and more creative textile solutions." The company also plans to increase R&D investment and leverage intelligent manufacturing equipment and designers to provide personalized customization services for customers, achieve continuous process improvement and standardized management, and thus drive the innovation and upgrading of the entire textile industry.

The technological upgrades of Zeroing Textiles not only bring customers a wider range of product choices but also set a new benchmark for the entire textile market. Our tenet: production efficiency, rigorous craftsmanship, strict quality control! We are committed to high-end garment embroidery design and production for over 20 years and equipped with new bead tube embroidery, laser bead embroidery, ribbon bead embroidery, and printing and embroidery integrated equipment. With the continuous rise in demand for personalized customization and high-end processes, the application of new technologies will further stimulate the innovation of the industry and present global consumers with more high-quality textiles that combine aesthetics and practicality.

RELATED INFORMATION

Spring breeze, all things budding——The 2025 China National Textile and Apparel Council Spring Joint Exhibition grandly opened at the Shanghai National Exhibition and Convention Center